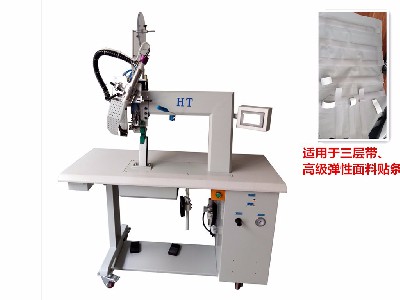

Jiangmen hot air seam sealing machine: mechanical seal flushing scheme

Mechanical seal flushing plan

Flushing of mechanical seal is a measure to control the temperature of mechanical seal and extend the service life of mechanical seal. The purpose of scouring is to take away heat, maintain and enhance smoothness, avoid liquid film gasification, avoid impurity accumulation, avoid air bag formation, etc.

According to the scouring form, it can be divided into internal scouring and external scouring. The internal scouring uses the transport medium for scouring, while the external scouring is through the introduction of external materials for scouring.

Internal scour, positive scour?

Operating principle: the sealing medium is led into the sealing chamber through the pipeline from the outlet end of the pump.

Useful scale: it is used to clean the medium. P1 is slightly greater than P. if the medium temperature is high or there are impurities, it is necessary to set coolers, filters and other equipment on the pipeline to treat the medium.

Recoil brush

Operating principle: the sealed medium of the operating host is introduced into the sealing cavity from the outlet end of the pump, and then flows back to the pump inlet through the pipeline.

Useful scale: it is used to clean the medium. P1 is slightly greater than P. if the medium temperature is high or there are impurities, it is necessary to set coolers, filters and other equipment on the pipeline to clean the medium

Total scour

Operating principle: the sealed medium of the operating host is introduced into the sealing chamber from the outlet end of the pump through the pipeline, and then flows back to the pump inlet through the pipeline after washing.

Useful scale: it is used for cleaning media, and P1 is close to p inlet and P outlet, and the cooling effect is better than the first two?

External scour

Operating principle: clean fluid from the external system is introduced into the sealing cavity to flush the mechanical seal.

Useful scale: the external scouring fluid pressure shall be 0.05--0.1mpa greater than that of the sealed medium, which is applicable to high-temperature medium or solid particles. The flow of scouring liquid shall not only ensure the cooling effect, but also properly control the flow of the controller.

Article source: Jiangmen hot air seam sealing machine www.jmhtjd. com. cn

-

06-22

What is the reason why the mold of Jiangmen ultrasonic machine is easy to crack

The simple crack of ultrasonic mold is mainly caused by two major aspects!I: the planning of the ultrasonic mold is unreasonable, the manufacturing cannot be precise, and the frequency has not reached

-

06-22

Technological advantages of Jiangmen ultrasonic plastic welding

Technological advantages of ultrasonic plastic weldingThe operation of ultrasonic welding machine principle is a fast, energy-saving and power-saving welding process, especially in the operation of th

-

06-22

Working principle and influencing factors of hot air seam sealing machine manufacturer

Operating principleThe hot air seam sealing machine is to use various external conditions (such as electric heating, high-frequency voltage and ultrasonic wave) to turn the sealing part of plastic fil

-

06-22

Automatic cutting of Jiangmen strip pasting machine before use

The belt slitting machine is an important part of the pre-treatment. The active cutting machine is used for inspection and filling with lubricating oil; After disassembling and inspecting the active c